Whether you have your own existing labels or you are starting from scratch,

bottling and packaging are fully customizable to meet your standards. Our

cutting-edge graphic design team is readily available to help bring your craziest

ideas to life.

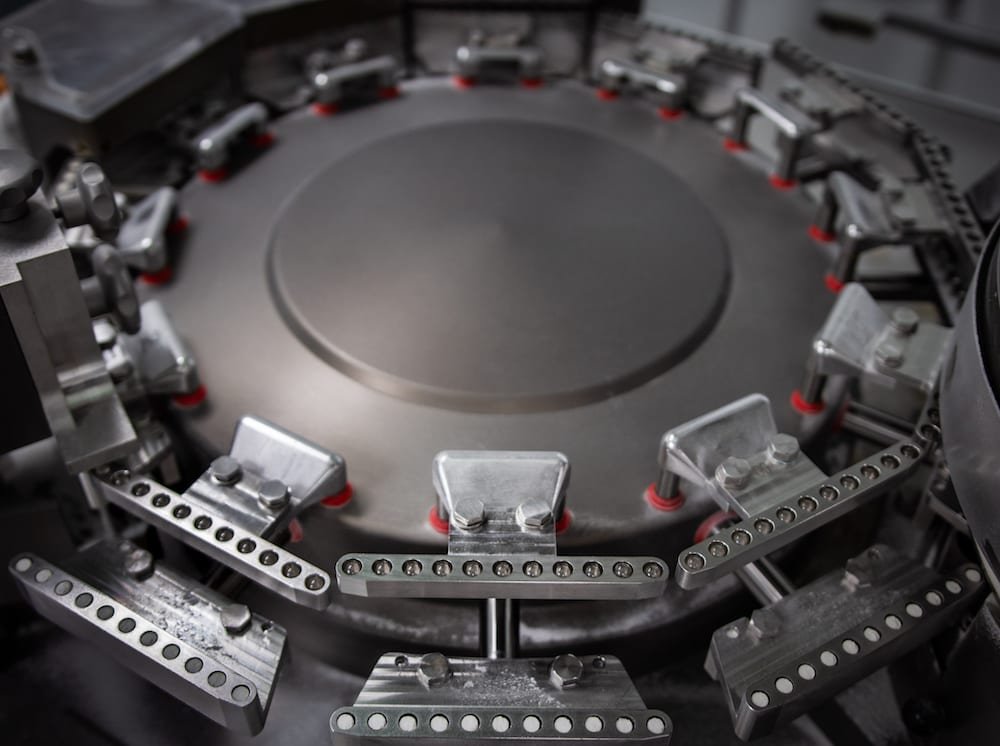

Once capsules are filled, they are brought to one of our bottling & packaging

assembly lines. The capsule production assembly line starts with a bottle rotator,

which funnels into two conveyors, one of which is a 16 station swift pack filled.

The other a four-station swift pack filled. Both filling bottles with capsules

simultaneously to double output.

Next, the bottles pass our automated desiccant pack inserter. Then they are filled

with cotton which is all an automated process. Next, the lid scrambler places the

lids on each bottle. Then the lid torque seals the lid on tight. Now the bottle is

now fully sealed before it passes through the label applicator.

Once labeled, bottles will find their way to another bottle rotator where personnel

is both able to check each product for the lid and label application before the

induction under the lid is heated to adhere to the brim of the bottle.

As the bottle undergoes our heat induction sealer process the same conveyor will

pass the bottle to our automated neck bander where our clients have the option of

clear or “sealed for your protection” neck bands which come both perforated and

unperforated.

All that is left for these sealed labeled capsule product bottles is to pass our

ink jet machine to apply either a “manufactured on a date” or expiration date which

is always followed by a batch-specific lot number for identification.

Bottles are cased into boxes and sent to our shipping department on palettes to be

sent to the client.